Valve Maintenance

Data Logging and Analysis

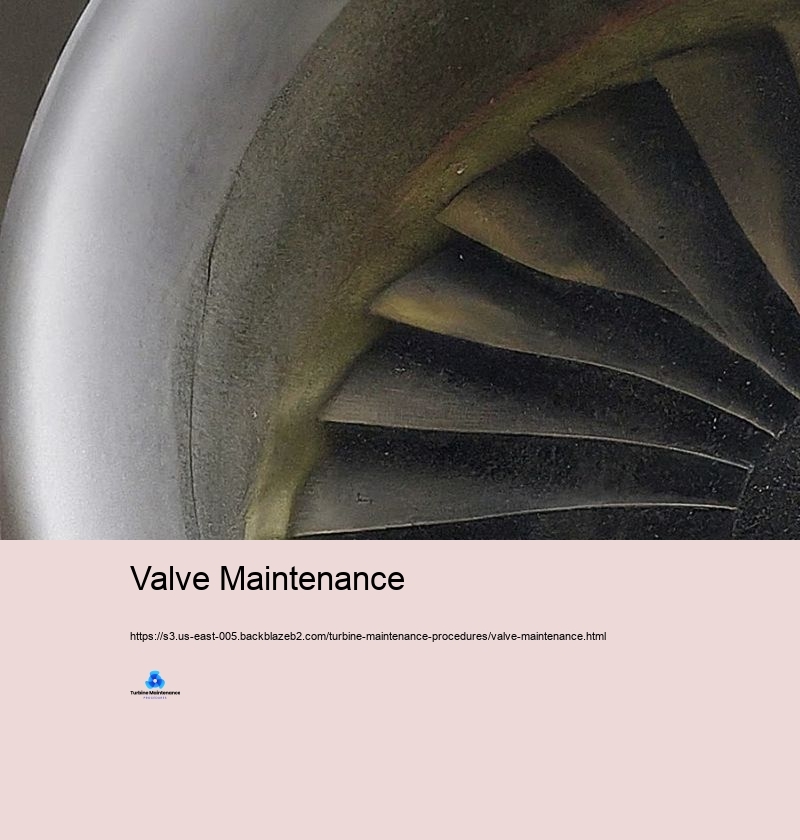

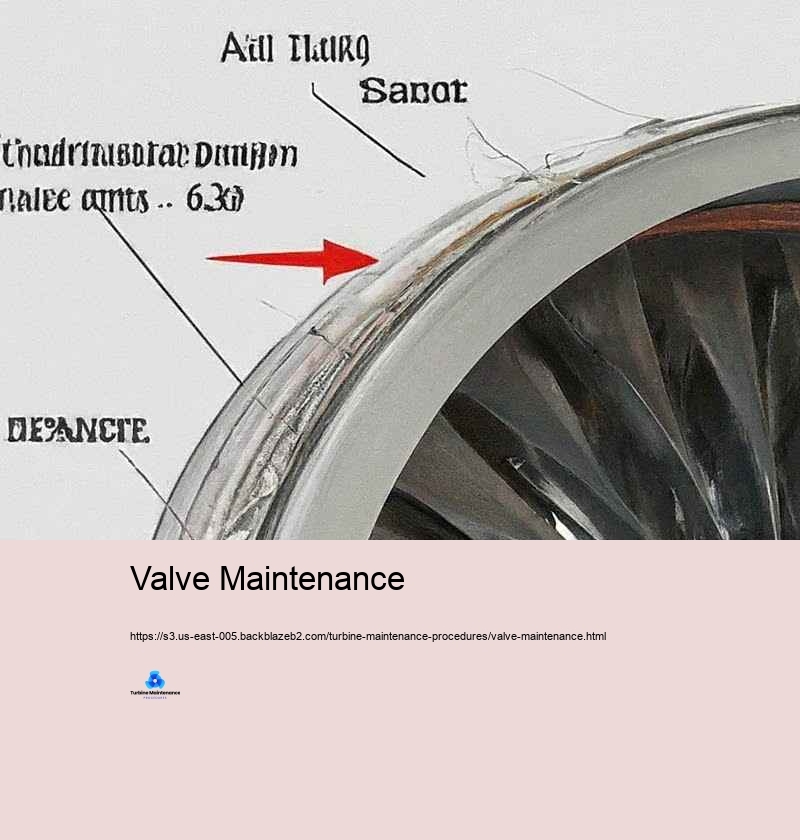

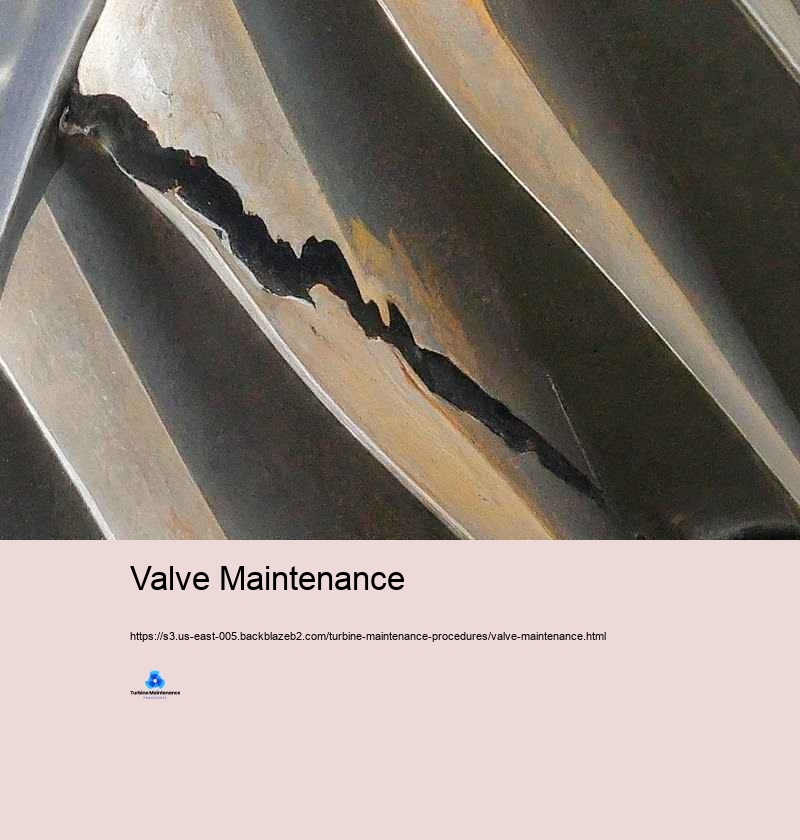

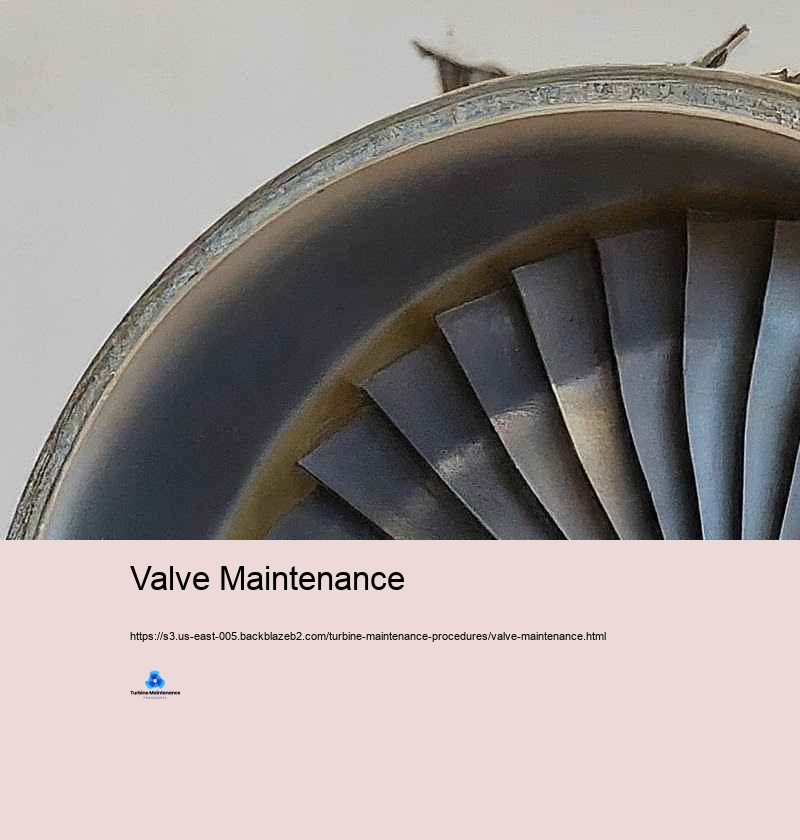

Turbine maintenance is a vital element of power generation, commercial procedures, and various other applications where wind turbines play a crucial feature. Appropriate maintenance makes certain optimum effectiveness, prolongs the life-span of the devices, and protects against expensive break downs. This intro to turbine maintenance finds the crucial concepts and strategies important for keeping these complex devices appropriately. At its core, turbine maintenance has to do with protecting the integrity and effectiveness of the turbine system. Turbines, whether vapor, gas, or hydraulic, are advanced items of machinery that transform power from a fluid (heavy steam, gas, or water) into power. The high-speed turning, severe temperature levels, and stress involved in their procedure make routine and detailed maintenance essential. Among the fundamental principles in turbine maintenance is preventive maintenance. This positive approach involves regularly arranged evaluations, cleansing, and tiny repair work to avoid substantial failings before they happen. Preventive maintenance usually contains tasks such as lubricating bearings, taking a look at and readjusting clearances, evaluating blades for wear or damage, and keeping track of resonance degrees. By addressing small troubles early, preventative maintenance can dramatically reduce the risk of disastrous failures and lengthen the turbine's functional life. Condition-based maintenance is an additional crucial idea that has gotten prominence with the introduction of innovative keeping track of modern technologies. This method counts on real-time info from sensing systems and keeping an eye on systems to identify when maintenance is required. Criteria such as vibration, temperature level, anxiety, and oil problem are continually monitored. Valve Maintenance When these specifications vary regular varieties, it suggests possible problems that need emphasis. Condition-based maintenance permits a lot more targeted and reliable maintenance tasks, decreasing unneeded downtime and making the most of source appropriation. Predictive maintenance takes condition-based maintenance an action in addition by using information analytics and expert system algorithms to forecast when failures are most likely to happen. By assessing historic information and existing running troubles, predictive maintenance systems can prepare for possible issues before they reveal as observable problems. This technique authorizations maintenance teams to plan therapies at one of the most appropriate times, lessening disturbance to procedures and making ideal use of the efficiency of maintenance jobs. Positioning is an important technique in turbine maintenance. Correct placement of the turbine shaft with the generator or driven gadgets is crucial for smooth procedure and long life. Imbalance can cause severe vibration, increased wear of bearings and seals, and reduced effectiveness. Regular placing checks and adjustments, regularly making use of laser positioning devices, are a common component of turbine maintenance programs. Balancing is another vital aspect of turbine maintenance. The high-speed turning of turbine elements means that also little discrepancies can lead to substantial vibration and put on. Dynamic balancing of blades and impellers is done to ensure smooth operation. This process includes including or getting rid of portions of weight at information indicate attain excellent balance. Typical vibration analysis help determine inequality problems early, permitting punctual adjustments. Evaluation and cleaning of turbine blades are crucial maintenance techniques. Blades can deal with various concerns such as disintegration, corrosion, fouling, or physical damages. Typical assessments, typically making use of borescopes or other non-destructive screening strategies, help identify these issues. Cleansing of blades, which might entail chemical cleansing or mechanical methods like grit blasting, helps keep wind resistant efficiency and protects against efficiency damage. Lubrication monitoring is a crucial aspect of turbine maintenance. Appropriate lubrication of bearings, gears, and other moving parts is essential for lowering massaging and use. This includes not just seeing to it an adequate supply of oiling compound nonetheless in addition examining its premium quality. Oil evaluation is a typical technique that helps find pollutants, use pieces, and adjustments in oil property or business residential properties that could show developing troubles in the turbine system. Seal maintenance is an added vital technique. Seals stop leakage of working liquids and lubes, and their stopping working can cause significant performance losses and feasible safety risks. Normal analysis and replacement of seals, specifically in high-pressure or high-temperature places, is a typical component of turbine maintenance regimens. Control system maintenance is considerably important as wind generators ended up being a whole lot even more automated and online managed. This entails normal checks and calibration of sensors, actuators, and control shutoffs. Software program application updates and cybersecurity actions are furthermore essential facets of modern turbine control system maintenance. Security is incredibly vital in all turbine maintenance tasks. Wind turbines consist of high energies, serious temperatures, and potentially harmful products. Rigorous adherence to security methods, including lockout/tagout procedures, constricted area gain access to procedures, and appropriate usage personal protective gadgets (PPE), is important. Safety and safety and security training and normal communication program for maintenance workers are essential approaches in turbine maintenance programs. Documentation and record-keeping are crucial practices in turbine maintenance. Comprehensive logs of all maintenance tasks, containing assessments, repair work services, and part substitutes, supply essential historical information for pattern assessment and future maintenance prep work. Several organizations presently use computerized maintenance monitoring systems (CMMS) to boost this treatment and help with info evaluation. Training and ability growth of maintenance workers is a repeating technique in turbine maintenance. As turbine technologies advance, maintenance techniques and devices in addition development. Normal training programs ensure that maintenance employees are current with the most recent maintenance techniques, evaluation tools, and safety procedures. Ecological considerations are becoming significantly vital in turbine maintenance. This consists of correct dealing with and disposal of unsafe items like used oils and cleaning up chemicals. Lots of maintenance methods now concentrate on minimizing ecological effect while making sure optimal turbine performance. Turbine maintenance is a challenging and diverse area that combines mechanical, electric, and progressively, digital proficiency. The essential principles of preventative, condition-based, and anticipating maintenance develop the structure of modern-day turbine maintenance approaches. Practices such as positioning, integrating, blade inspection and cleansing, lubrication administration, and control system maintenance are crucial for seeing to it the integrity, efficiency, and resilience of turbine systems. As turbine modern technologies remain to development, maintenance methods will certainly furthermore advance, incorporating brand-new developments and techniques to meet the difficulties of keeping these essential tools in an ever-changing power landscape.

Compressor Blades